Along with our experiences we have taken into consideration our customers requirements and their commonly held standard practices for gauge building. This Gauge Standard is designed as a guide for the design manufacture and approval of checking gauges su itable for our product.

Feature Windows Hospital Interior Design Healthcare Design Hospital Interior

522 the fixture concepts shall accurately show the intent of the design how the part will nest datum locations types of checks clamp locations etc in a manor that is consistent with the geometric dimensioning and tolerancing of.

. A designer should have a good common sense in observing the direction of cutting forces too so as to decide the right type of location butting and clamping of the component. This deflection of fixture is caused because of forces of cutting clamping of the workpiece or clamping to the machine table. Checking fixture design guidelines Written By arethaquain36025 Friday May 6 2022 Add Comment Edit.

The device under test test equipment and the fixturing to make the connections between them. For example pipe-sizing requirements that were set more than 50 years ago remain unchanged even though plumbing fixture flow rates flush. The main frame of the fixture should have the mass to prevent vibration and chatter.

A fixture having the added function of guiding a tool is called a. 521 fixture concept must be submitted to bae within one week after kick off of any new check fixture. Locating a part to be machined involves mainly three steps.

A The main frame of fixture must be strong enough so that deflection of the fixture is as minimum as possible. The des ign and creation of the 2D and 3D of the project. Fixture Design Fundamentals of Tool Design Study Guide DV07PUB3 - 4 - Review Questions 1.

Have readily accessible features which allow dimensional data to be obtained and to provide conformance to design and manufacturing requirements. The definition of a checking fixture will have important consequences on. Not only familiar with European and Japanese technical standard but also establish our own standards and perfect database.

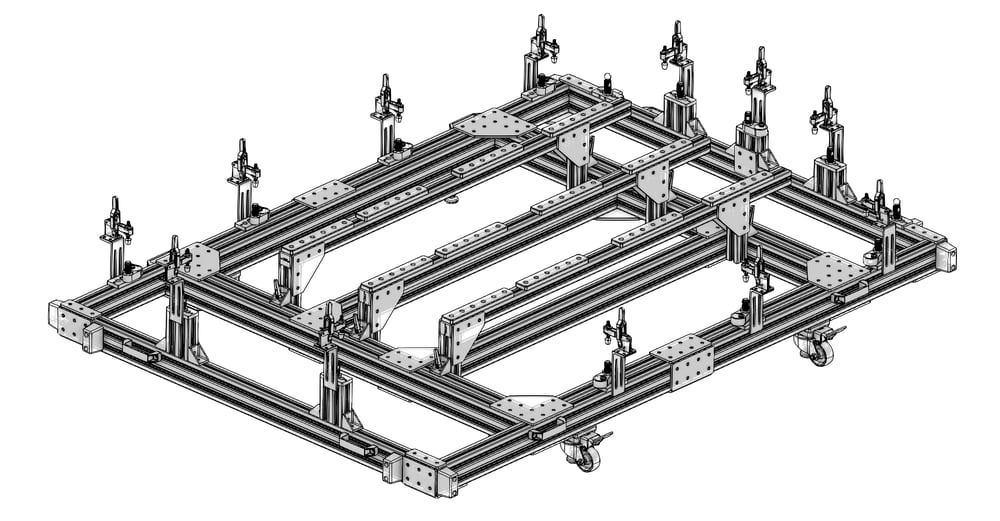

We are skilled in designing of BIW interior. In the automotive industry a checking fixture is used to examine the final components of the sheet metal body parts such that when all parts of the vehicle chassis are placed in a BIW fixture they are accurately positioned. The MNA representative and the Vendor must sign the final design.

This Network Rail standard specifies the requirements for the design and construction of track with line speeds up to 125 mph. Fixture planning fixture layout design fixture element design tool body design etc. Checking fixture design guidelines Written By louiezoldak24685 Friday April 22 2022 Add Comment Edit If the checking fixture were to exceed the CMM table size additional feet will be needed to sit level.

Base plate must fully encapsulated the part and any swing out details in their fully opened position. With regard to question 2 clockwise and counter. The number of degrees of part freedom is.

E t The manufa cture of every lemen of the checking fixture. Professional designing software of RIXING are CATIA UG AutoCAD. Testing of electronic assemblies involves three elements.

This document is intended as a guideline to make fixture sources aware of the build requirements and buyoff criteria that will provide the basis for fixture approval and invoice payment. Domain courses include CAD with engineering fundamentals like material selection manufacturing process design. Checklist for Check-Fixtures Automotive Check Fixtures - Injection Molding thenson Mar 5 2009 T thenson Starting to get Involved Mar 5 2009 1 Our company is rather new with automotive checkfixtures design concepts construction and qualification.

62 In the absence of a qualified stamped base checking fixtures are to be provided with three tooling. Phase I 1 CASI 2002 AY PROGRAM PHASE I FINAL PROJECT REPORT FIXTURE DESIGN CRITERIA. Always aim at having a fixed rigid part of the fixture element to take up the cutting forces.

They are listed in Figure 14 in their natural sequence although they may be developed in parallel and not necessarily as a series of isolated activities in actual execution. A BIW Body in White fixture is a manufacturing tool that holds 3-dimensional parts together which are to be welded. This guideline is to be considered as a minimum requirement.

Jigs and fixtures have an undeniable role in the overall art of metalworking. Take note of the following guidelines. A MNA representative must approve the initial gage design and subsequent design changes.

Fixture design deals. PHASE I Shivakumar Raman PhD Professor Aashish Wadke Research Assistant Muthukumar Trichy Research Assistant Nick Niver Research Assistant Chris Way Research Assistant School of Industrial Engineering University of Oklahoma 202 W. Supporting Positioning and Clamping.

It is preferred that two reviews take place one at or about 50 completion and one at 100 completion. The materials to be used the elements of metrology to be included and the surface and heat treatments. Two main intentions when placing a job on a jigfixture are.

Curbing all six degrees of movement so that the part cannot budge. All checking fixtures must have four tapped holes M16 present on the base plate. Precisely positioning the part at the desired coordinates.

Today this process is primarily handled with advanced technology like CNC machines. If the base plate exceeds 60 in length the location of the tapped holes should be 600mm from the center in both direction. Provide consistent and accurate locating points to achieve maximum repeatability and reproducibility.

Base plate to be constructed of aluminum 1 thick with machined edges parallel to body or work lines and machined numerals as per location. To design and build a high performance test system an engineer must understand how the measurement signals will travel from the instrument to the pins that touch the product under test. All the data including input or output data are managed in our servers.

The Jigs and fixtures design as well as the clamping support and locating technique of your machine setup must work in tandem to create flawless products or prototypes. Fixture design consists of a number of distinct activities. Work-station is the standard system for checking fixture design.

Checking fixtures and CMM holding fixtures are tools that dimensionally qualify detail parts or assemblies and audit manufacturing process variations. Design of fixture checking including Position of hole and slot. We are specifically dealing with Toyota as our end customer.

The design does not have to be signed at the 50 review but must be for the 100 review.

14 Bathroom Design Guidelines Illustrated 2 Kitchen And Bath Design Bathroom Plan Design Guidelines

3 2 1 Principle Used For Jig And Fixture Locating Method

Designing Jigs And Fixtures Design Guide Vention

Plenum Hvac Plenum Design Hvac Return Hvac Design How To Plan Fan Coil Unit

Innisfree Gangnam Seoul South Korea Mapos Architects Dpc Archinect Pharmacy Design Supermarket Design Retail Store Design

Design Principles Of Jigs And Fixtures Prescient Technologies

Understanding Fixturing Constraints Locator Clamping Support And Guide

0 comments

Post a Comment